RMC Process Control

Today more than ever, business and operational processes greatly depend on improving and streamlining complex production environments, remote field operations, and management control of the supply chain. Improving business process automation and remote workforce management have emerged as the crucial elements of advancing operational efficiencies.

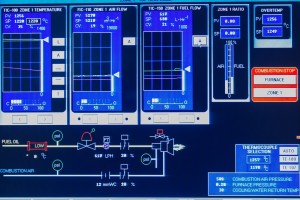

Process Control: PLC and DCS Monitoring and Management are the Heart Process Automation

Distributed Control Systems (DCS) are central control systems utilized in controlling analog devices throughout production processes provide alternatives to automated process control.

Sensor integration and SMART-Devices deployment provide feedback and control options for many processes and production operations. Each process has a separate set of sensors and controller devices generating the necessary output information regarding the status inside the production process. The PLCs, sensors, SMART-Devices are the foundation of Machine Execution Systems (MES) and form the central controller for MMI [Man Machine Interface] architecture. Information originated from these devices allow for corrective controls to be communicated to production equipment.

Modern PLCs, sensors, SMART-Devices & DCSs deliver enormous capacity for plant automation environments. Although these is significant differences in the capabilities of each of these options, The combination of these sensors and devices when integrated into a well-orchestrated production environment work in concert to provide a more robust remote process control system maintaining production volumes and insuring continuous improvement in product quality.